To start with the basics,

a fibreglass or GRP (glass reinforced plastic) moulding is

made up of thin glass filaments or strands, either woven into

cloth, or in randomly assembled mats, bound together with

a plastic resin. On their own the glass strands are strong

but not stiff, and the resin is stiff but not strong. When

joined together as the resin sets chemically, the result is

both strong and stiff, and very durable. Ideally the final

moulding should have lots of glass and only enough resin to

hold it together and seal in the glass strands, but most conventional

mouldings have much more resin than this ideal. |

Various types of resins, and various

types of cloths and mats are used. A typical moulded GRP yacht

hull will have as its outer layer a thin coating of a special

resin called gelcoat, which forms the hard glossy outer surface

of the hull. Inside this will be several layers of glass mat,

often reinforced with one or more layers of ‘woven rovings’

- glass strands woven into a thick cloth, all bound together

into a single structure by the resin. Most yacht builders * have usually moulded the hulls layer by layer,

letting one layer of glass and resin set before putting on

the next. Provided the hull is moulded properly, without long

delays between layers, all parts of the moulding bond chemically

into a single body - unlike, for example plywood, where a

number of distinct layers are glued together. |

SCRIMP and other resin infusion or vacuum bagging processes |

* The exception to the ‘layer by

layer’ moulding process is vacuum bagging or resin infusion

moulding, where all the dry layers of glass cloth and mat

are laid in a mould, and held in place by either an inflated

plastic balloon, or another close-matching mould. The resin

is then drawn into the fibres by vacuum suction. The process

is more expensive than standard moulding, but is capable of

producing very light, strong laminates with a high glass content,

and very importantly, very few air bubbles in the resin/glass

composite. Resin infusion moulding, using vinylester resins,

ought to produce GRP hulls that are virtually proof against

osmosis, but the process and materials has not been around

long enough for this to be proven. These types of mouldings

originally were most often used for high-tech racing hulls,

often in conjunction with carbon fibre and/or kevlar instead

of glass fibres, mainly to allow lighter weight construction.

The system is however becoming much more common for mainstream

cruising boat building, as in addition to using lower quantities of expensive resin, the process is also more environmentally

friendly than conventional lay-up moulding |

The resins used vary. The earliest resins used, back in the

1960s, were orthopthalic polyester resins. By around 1980, isopthalic

polyester resins started to be used as well by some builders, as

they were more water resistant, although more expensive. Most builders

used these more expensive isopthalic resins only for the first outer

coats, and then saved money by using the cheaper orthopthalic resins

for the inner layers. A few used isopthalic all the way through.

Some builders have also used double layers of gelcoat, in an attempt

to stop osmosis occurring. It did not generally help to stop osmosis

occurring. |

The latest type of resin is called vinylester, and is said to be

even more waterproof than isopthalic polyester. It is of course

even more expensive, and the same option of using only as an outer

layer is open to builders if they are trying to cut costs, as all

yacht builders almost invariably are. |

text below from a brochure for a £250,000 plus sailing

yacht |

The cost difference between

'vinyl', 'iso' and 'ortho' resins is such that many yacht

builders still only use isopthalic or vinylester resins for

the outer layers, completing the inner bulk of the fibreglass

layup with cheaper orthopthalic resins, and non powder bound

mat. Note the exact wording of the hull specification at right,

taken word for word from the brochure for a very expensive

yacht. There are however some builders who are using isopthalic

or vinylester resins throughout - those who do generally tell

you! |

|

While new yacht brochures will go to some lengths to tell

you about the exotic woods used in the interior, the Corian

worktops or the leather covered wheel, very few will actually

give a layup specification for the hull. Most do however

mention the gelcoat used, some builders claiming that 'their'

special gelcoat will prevent osmosis. Unfortunately they

only guarantee this for five years.

|

Despite most people’s assumptions to the contrary, fibreglass mouldings, no matter what resins are used, are

not actually totally waterproof. Individual water

molecules are so small that they can actually find their way into

and ultimately right through the layers of glass and resin forming

a boat hull, or GRP pond liner. This in itself is not osmosis, it

is simply a minute degree of permeability of the material. |

The problems start to occur when the water molecules migrating

into and through the GRP encounter other chemicals inside the laminate,

primarily water-soluble materials (WSMs) such as the the emulsion

binders used to hold some types of glass mat together before it is moulded,

or pockets of uncured or only partly cured resins in the moulding.

The water molecules can then have a chemical reaction with these

substances, forming larger molecules of a new chemical, often acidic

- which unlike the original small water molecules, cannot carry

on passing through the GRP. These larger molecules are then trapped.

This is the point at which osmosis actually starts. The process

of osmosis is the same mechanism by which plants and trees draw

water up from the soil to their branches and leaves, and is described

in a dictionary as:- |

os·mo·sis (oz-mo'sis,

os-)

Diffusion of fluid through a semipermeable membrane from a solution

with a low solute concentration to a solution with a higher solute

concentration until there is an equal concentration of fluid on

both sides of the membrane. The tendency of fluids to diffuse in

such a manner. |

The important parts are that the hull is not waterproof (it

is a semi-permeable material), and that osmosis causes a low concentration

fluid (water) to pass through the hull to join the higher concentration

fluid (the chemical mix formed by the water plus WSM) inside the

laminate). |

Pressure is thus built up inside the laminate. If this process

takes place in a solid part of the laminate, there is usually no

problem as the structure is strong enough to contain the pressure.

If however it takes place on the boundary of a small air-bubble

in the moulding, or at a point where layers of GRP are poorly bonded,

the resultant new chemical compound or compounds slowly fill up

the bubbles or the minute gaps between layers with liquid. Almost

all mouldings have these air bubbles and small areas of poor bonding,

although they should not. Ideally the resin should totally fill

the gaps between the glass strands, and every layer should perfectly

bond to the next. In practice, however, this is extremely difficult

to achieve with conventional moulding techniques. |

The process of osmosis in GRP is however very slow, unless the

moulding is appallingly badly made, and no matter how long it remains

in water a typical GRP laminate cannot absorb more than about 2-3%

of it’s own weight of water. Surveyors and boatyards (and

some brokers, including Yachtsnet) put moisture meters on yachts hulls to check the moisture

content, on the basis, often but not always correct, that high moisture

levels in the GRP are a precursor to the development of blisters. |

If this osmosis (using the term in it’s correct manner

for once) was all that happened, it would be a very minor problem.

Even completely saturated with water molecules, a GRP laminate still

retains most of it’s strength, although it does become slightly

more flexible and weighs a tiny bit more. Racers who want stiff hulls with the absolute minimum

weight already mostly keep their boats ashore when not sailing,

and for any properly built cruising boat 2% or so extra weight and

a trace more flexibility in the structure should not be a problem. |

Once again, if the air bubble simply filled with

this acidic compound, the problem would still be relatively minor.

However the nature of the osmosis process is that water molecules

keep osmosing through the laminate, and join the chemicals in the

bubble, steadily building up hydraulic pressure. Eventually this

causes the surface of the moulding to blister. |

These blisters are the typical sign of what boat-owners

usually refer to as ‘osmosis’. When pierced these blisters

will give off a small amount of chemical-smelling (usually vinegary)

liquid - which is the juice built up inside the pressure-raised

blisters. The term ‘blister juice’ is often used. This

‘blister juice’, which is usually acid, can break down

the polyester. This breakdown process is known as hydrolysis,

and causes a reduction in strength of the laminate. This is however

normally very localised, and the moulding as a whole will still

retain most of it’s strength despite blistering. Most blisters

are in the interface between the gelcoat and the structural laminate,

and have very little effect on the hull's overall strength. Only

if the blisters are very large, or very deep-seated, are blisters

generally a structural problem. |

|

Two photos of the same blisters on

the topsides of a yacht - chosen for the clear view of the blisters |

|

Blisters are often difficult to see - it is fairly rare

to find them as obvious as the medium sized (approx 3/4 "

diameter) blister seen here. Another smaller blister is visible

to the far left of the picture |

|

In a closer view (with the image contrast increased) you

can also see faint traces of a group of smaller pimple-sized blisters

forming in the centre of the picture above, closer to the waterline

|

It is rare, but not that rare, to find osmotic

blisters above the waterline. They can however occur anywhere on

a GRP moulding. More often they are found underwater, often partially

obscured by layers of antifouling paint, though they are also very

common inside glassfibre fresh water tanks. When looking for blisters

on a hull, shining a light along the hull surface can help, as can

wetting areas of the antifouled hull surface to make it shinier.

The yacht in the photos above had been given a below-waterline 'osmosis

treatment' at some previous date, and the bottom was now in good

condition, with low moisture levels by a moisture meter. The topsides

however gave very high readings, and had a fair number of blisters. |

One scientific study of the problem of blistering was given

in the paper "Causes

of Boat hull blistering". This 1987 study was carried out

by Thomas Rockett, Ph.D. and Vincent Rose, Ph.D., at the University

of Rhode Island, and was partly funded by the US Coastguard Service. |

Yacht hulls are typically built with a substantial

safety margin of thickness and strength, and it is incredibly rare

to find a yacht hull that is seriously weakened even by very advanced

osmotic blistering. Often, the older the boat the heavier the original

construction, and the greater margin of safety. Most blistering

occurs near the outer surface of the moulding, usually in the borderline

between gelcoat and underlying layers of resin and glass - and the

gelcoat is largely cosmetic and not structural. |

|

Many older and more traditional GRP yachts are built with what

is, by modern standards, a massively heavy GRP layup. Although

many of these boats may have been built with what is now known

to be less than ideal materials, often in conditions far removed

from a modern climate-controlled moulding shop, the fact remains

that many such boats, dating back to the 1960s, 1970s and occasionally

even earlier, are still around, and in many cases exhibiting no

signs of osmosis. On a very heavily built GRP hull such as this

Seadog ketch, even quite severe osmotic blistering of the gelcoat

is unlikely to weaken the hull in any significant way. Whether

typical modern mass production yacht hulls have as great a margin

of safety of structural strength is dubious

(the boat shown at left here did not, by the way, have any signs

of osmosis on its last survey!) |

"What is universally agreed is that

osmosis discovered within the very early years

of a vessel's life

is bad .... " from 'Surveying Small Craft' by Ian Nicolson |

Once blisters in the gelcoat have appeared, a period

of storage ashore, particularly in warm dry weather, may cause many

shallower blisters to apparently disappear, as most of the water

in the blisters dries out. What is left behind, though, is a highly

concentrated solution or even crystals of the 'blister juice', which

will usually rapidly re-absorb water once the hull is put back into

the water. |

Normal winter periods ashore definitely slow down

the process of yacht hulls developing osmosis, as they do

partially dry out each winter, even in northern European weather. However you cannot simply

dry out a wet hull by leaving the boat ashore for a few

months - water that took fifteen or twenty years to get

into a laminate does not escape in months, unless the gelcoat

is removed as is done in "osmosis treatments"

|

|

As brokers, we have many times seen situations where an older boat that has previously always been wintered ashore every year, is for once left afloat for an 18 or 20 month period, and is found to have developed blisters when lifted for survey.

|

|

The process of osmosis is fairly well advanced by

the time visible blisters start to appear on the bottom of a hull. It must be realised however, that

the process starts the minute a new yacht is craned into the water,

or even when it’s hull and deck first gets rained on as it

is wheeled out of the factory. |

Another facet of water absorption into a hull is

known as ‘wicking’. This refers to

the ability of water molecules to creep along the boundary of the

individual strands of glass within the moulding. A totally dry moulding,

if moulded with unpigmented resin, will be virtually transparent. If you

can see individual strands of glass as whitish threads, what you

are seeing is not the glass strands themselves, but microscopic

traces of water around the strands. This ‘wicking’ is

an indication that there is a significant amount of moisture in

the resin, and is often a precursor to or accompanies blistering.

|

Unless very severe, wicking is much more difficult to detect if

the layup moulding resin is white or coloured rather than clear.

It is generally accepted that clear resin is less likely to suffer

from osmosis or wicking than pigmented resins, and many quality

builders use clear resins for at least the underwater areas of their

hulls. We thus have a "Catch 22" situation that the better

quality mouldings, with clear resins used, are more likely to be

found to have wicking - 'found' being the significant word! |

Just as the tests for astronauts in the space programme

proved that anyone would get motion sickness if shaken around enough,

all GRP yachts, from the day they are built, suffer from osmosis.

Manufacturers now typically offer five year hull warranties, and

it has been said - cynically but probably accurately - that their

main concern is not to build yachts that do not suffer osmosis,

but to do just enough that they don’t get visible blisters

within the warranty period, which for most yachts is 5 years. Several

US manufacturers of small power boats, however, now state in their

warranty conditions that the boats are not to be left afloat for

more than 2 weeks, or the warranty against blisters is invalid!

At least one US builder will not offer any warranty at all against

blisters. |

The fact remains that in practice some yachts ‘get

osmosis’ - ie blisters, and some don’t. It is known

that several factors increase the likelihood of blistering. These

are |

|

Long periods afloat without layups |

|

Warm tropical waters |

|

Fresh water is worse than salt water |

|

Coloured resins (including white - the most common) are

worse than clear resins |

Historically, there have been some models and batches of boats

that have suffered severely from blistering. Often this was due

to changes in layup specification, and use of new materials. For

example, it is now known that the use of PVA emulsion bound glass

mats is bad practice. Emulsion bound mats were introduced in the

1960s as an improvement, and accepted by Lloyds and other classification

societies for standards of hull construction for almost 20 years.

Emulsion bound mats are now regarded as bad, as the PVA is water

soluble, and tends to encourage wicking. Mats used now should be

powder bound, especially in the outer layers of a laminate. Nevertheless,

plenty of yacht builders still use emulsion bound glass mat in inner layers

of hull layups. |

Whilst some builders, including those who produce

some very expensive boats, have had runs of boats prone to blistering,

they have also turned out apparently identical boats that have not

blistered. Current thinking is that cleanliness, temperature and

humidity control in the moulding shop, and precision of the mix

of resins, are the key to building boats that will not blister.

Nevertheless I know of one builder who worked in a dirty corrugated

iron shed where the climate control was dependent on whether an easterly

wind blew through the gaps in the door. His boats actually had

a rather good reputation for ‘not getting osmosis’. |

Whilst all GRP boats slowly absorb some water, it

should not be fast. Visible blisters or wicking are an indication

of a well developed absorption of water, and if they occur in the

first few years of a boats life are an indication of a moulding

problem of some sort, whether it be poor materials, poor workmanship

by the laminators, or any other quality control problem ranging

from sawdust getting into the moulding to a prolonged delay (factory

holiday - several people off with flu?) between laminating up the

various layers that form the hull. If the builder is still trading

they will normally repair this under warranty. Unfortunately whilst

the original bare hull moulding of a £150,000 yacht might

only cost £15,000 to mould, it will perhaps cost another £100,000

to fit it out even if using every easily removable part from the faulty

hull. So the builders will ‘treat’ the ‘osmosis’

by the standard current method, namely stripping off the external

gelcoat, drying out, and recoating with epoxy fillers. As this new

external coating is essentially ‘glued on’, and not

chemically part of the original moulding as was the original gelcoat,

it can be argued that the boat is substantially devalued by this

repair. |

By around fifteen years age it is reasonably common to find

that yacht hulls have a moderate to high moisture content. Some

may also have developed a few blisters, often on the rudder blade. This is absolutely typical,

and not necessarily a sign that there is anything terribly wrong

with the boat. |

If a yacht reaches twentyfive or thirty years of age without high

moisture content or visible blisters it is actually a bit of a surprise. |

These timescales assume a standard modern mass production

yacht, given average use of perhaps seven or eight months afloat

a year, with just antifouling paint on the bottom. Painting the hull bottom with epoxy coatings can considerably, but

not totally, slow down the rate of water absorption, and some builders

do this from new (including the local tin-shed boatbuilder referred

to earlier). Opinions vary as to the effectiveness of epoxying or

painting once there is already some moisture in the moulding. |

On boats which have been painted or epoxied, it is not

uncommon to find, after a few years, blisters in the interface

between the epoxy/paint coating and the gelcoat. This is

obviously much less of a problem than blisters under the gelcoat

itself. Some experts believe that paint or epoxy coatings

are not a 'once-and-for-all' protection, but should be renewed

regularly to maintain effectiveness. |

Treatments for ‘osmosis’ range

from: |

|

Do nothing. On an old, heavily

built boat, this is a genuine option. If there are no blisters

I would definitely do nothing even if a moisture meter shows

very high readings. If there are blisters but they are small

and not too many they are not likely to have any significant

effect on the structural strength |

"Thousands of boats are sailing happily

throughout the world with high moisture readings and an underwater

hull resembling bubble wrap. Just keep an eye on the situation.

..." from 'Practical Boat Owner' August 2005 |

|

Local treatment. Cut or grind open individual

blisters, repeatedly wash out with hot water or steam, to

remove the ‘blister juice’ from any blisters,

dry thoroughly and fill with epoxy paste (not car body filler).

Next winter you may have a few more blisters - usually in

different places. The fact that they are usually in different

places is a significant one - you are not getting blisters

re-occurring but new ones developing. Hugo du Plessis, author

of what is virtually the standard reference work on the construction

of GRP yachts, regards this as the best option in almost all

cases, and says total gelcoat replacement (see below) should

be an absolute last recourse |

"Many gel coats which could be saved at no great

cost are destroyed quite unnecessarily...." from

'Fibreglass Boats' 4th Edition, 2006, by Hugo du Plessis |

|

Go to your local ‘Osmosis Treatment Centre’ and pay rather a lot to have the gelcoat removed,

the hull washed and dried out, and the hull recoated with

epoxy. The smaller and older the boat the less cost-effective

this is. Treating an old 25 foot boat could cost

£5,000 plus on a boat perhaps only worth not much more than the same amount. On

a 50-footer worth £150,000 the cost might be £20,000

- a far lower proportion of the boat’s value. Yards

used to offer a five year warranty with this work - many no

longer do so, or charge extra if you want the warranty (they

buy insurance against claims). |

"The sooner you treat it the less it will cost

you and the more your boat will retain its value....." from the 2011 website of a company specialising in osmosis

treatments

|

* One factor that is becoming increasingly

apparent is that early osmosis treatment on the basis of high

moisture readings alone, or a few small blisters, is not actually a

good idea - it seems to be better to allow the blistering

to develop fully before carrying out an "osmosis treatment". |

If you are keeping the boat yourself you can look at these options and decide which way to go depending

on inclination, temperament and bank balance. |

If you are trying to sell the boat,

other factors come into play. Buyers almost always prefer boats

without blisters, and even if there are no actual blisters, once

a surveyor puts a moisture meter on the hull and says there is moisture

in there, most buyers think “.... if I buy this it’ll

get blisters soon and then I’ll have to spend thousands on

an osmosis treatment” - so a ‘wet’ hull,

even if unblistered, is much more difficult to sell. |

Unfortunately it is a common perception that any

boat with a high moisture content or blisters, MUST be treated,

and that the only treatment is the full Monty - strip off all the

gelcoat and recoat. Boatyards like doing the work: it is profitable,

and can be time-scheduled in to when staff have some free time.

Some surveyors like to recommend it as it means they’ve ‘covered

their backs’ against a later claim that they didn’t

pick up a defect. |

It is certainly easier to sell an boat with no blisters

and a low moisture content - so particularly on higher value boats (a

£15,000 hit on a £100,000 sale is not too disastrous)

getting an ‘osmosis treatment’ done is often the way

to go. You do however have to allow time for the work to be done

- ranging from about 4 weeks if forced drying or a process called

‘hot-vac’ is used, to three to six months or even longer

if the hull is left to dry out naturally in the open air, although

shielded from rain. |

If you go for the option of treating blisters locally,

the hull will still be wet, although with no blisters. A surveyor

will probably report this, and a phrase along the lines of “....

it may be necessary to carry out an osmosis treatment in a year

or two” is very common in survey reports. Certainly it

may be. Or it may not. Either way the surveyor can’t be sued

for negligence for failing to point something out. |

If you are buying a boat, obviously

it is preferable to have one with no blisters and a dry hull (low

moisture levels on the magic meter). If this condition is achieved

by the original hull surface, with no repairs, it is clearly better

than a similar boat that is also dry and with no blisters, but achieved

by having recently had an ‘osmosis treatment’. The treatments

are not cures - they simply 'restart the clock' on a progressive

slow period of absorption of water again, as even epoxy coatings are

not totally waterproof. Nevertheless, do not reject an older boat just because it has had an osmosis treatment - as it may be quite impossible to find another of the same age and type with a dry original hull surface.

|

If you are looking to buy a small - 20 to 30 foot or so - boat at relatively low cost you will inevitably be looking at boats of 20 or more years of age. It is almost inevitable that most of these will have either highish moisture levels in the hull, or have some blisters. Even if blisters are not obvious when you look at the boat yourself, once a surveyor has scraped off antifouling in patches it is likely that he will find tiny beginnings of blisters - "baby blisters" as one surveyor describes them. You can go through a lot of expensive surveys, rejecting boats, before you find the rare one that has a perfect hull. |

Occasionally buyers will happily accept a boat with

high moisture content or obvious blisters - on the ground that they can

haggle down the price as a result. They then may or may not then

get some form of treatment done - perhaps just before they sell

it on a few years later. |

If a seller is genuinely unaware of the moisture

content/blisters, a situation which is not uncommon, as many blisters

are small and can be invisible under layers of antifouling, and this is discovered

on survey, a common compromise is to knock about half the cost of

an ‘osmosis treatment’ for that size of boat off the

price. It is unfair to expect the owner to take the full price off,

as if the gelcoat is replaced the boat is more saleable, and hence

more valuable, as it then has a known low moisture content and no

blisters. This "split the cost" compromise is often agreed for medium to large boats, but for small, low value boats the cost of having a full osmosis treatment done is so high in relation to the boat's value that it is rarely possible to reach this compromise between buyer and seller. |

|

Moisture meters |

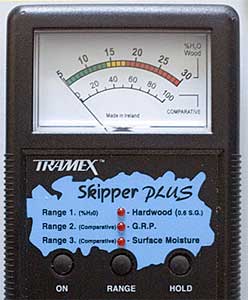

The first thing to know about moisture meters

is that they don’t actually measure moisture. They

measure conductivity. My Tramex meter (a popular model with surveyors

and boatyards) invariably shows a very high moisture reading on

the absolutely dry glass top of my living room coffee

table. It’s measuring the presence of minute traces of carbon

(an electrical conductor) in the lightly smoked glass. |

For this reason these meters are only of value when used comparatively.

A reading of the underwater body alone is valueless - the glassfibre

gelcoat may be made with pigment that is itself slightly conductive. For

this reason it is usual for test readings also to be made on the

topsides - if the hull topsides well above the waterline consistently

read medium or high then there is certainly reason to doubt whether a high reading below the waterline really means moisture - although it could of course

also be the case that there is water in the topsides laminate

too - perhaps from leaks along the gunwale joint. |

Tramex meters read

quite deep into the moulding - deep enough to be fooled by materials

inside the hull. I have been told by a surveyor that the bilge keels

of a Seadog ketch had a surprisingly high moisture level compared

to the rest of the hull. I told him (although I’m sure he

would have worked it out for himself eventually) that these hollow

bilge keels were the water tanks in this design, and currently near

full. Bilge water in compartments inside the hull, metal reinforcements,

wiring harnesses, even condensation inside inner hull linings, can

affect the readings of meters. |

|

Sovereign meters, another common

type, generally read to a much shallower depth. This can be either

good or bad, depending on what you are trying to measure - surface

moisture or deep seated moisture. The current version of Tramex meters have

an extra mode switch to reduce the depth of the reading. To make

matters still more complex, the Sovereign and Tramex meters give

results on different scales of sensitivity - Tramex from 0-30 and 0-100 and Sovereign from

0-25 and 0-100. So a reading of ‘20' could be quite good or quite bad,

depending on which meter was used and on which scale. Most yacht surveyors quote Tramex readings as 0-100 and Sovereign readings as 0-25. |

None of these moisture meters give an absolute reading

of the amount of water in a structure: all they do is tell you that

if readings in one area are higher than another, then that area

might be wetter. It also might not. You could be reading

the presence of something else that conducts electricity. |

It is common for surveyors to take moisture readings

on hulls during a brief (often just 1 hour or so) lift-out. Particularly

with older boats, built using orthopthalic resins, high readings

will almost always be obtained immediately after hauling out, but

these will often drop substantially if left ashore for a few days. This effect

is less pronounced with isopthalic or vinylester resins - they are

better at keeping out the water in the first place, but do not let

it dry out again as easily. |

Whilst epoxy coatings offer some protection to hulls from water absorption, the epoxies themselves can absorb water, and be slow to dry out - up to two weeks is sometimes quoted. For most pre-purchase yacht surveys, having two weeks ashore before readings are taken may not be practical. |

|

The International Institute of Marine Surveyors

Code of Practice for marine surveyors recommends that "...

ideally the vessel should have been out of water for at least 24

hours". It also sets out a complex form of statistical

calculation to reduce randomness of readings and take into account

local temperature and humidity when measurements are taken. I have

yet to see a yacht survey report that actually used this calculation. |

There is a common myth that drying out a boat with an osmosis treatment will make the boat much lighter, as tons of water will have soaked into the hull. In fact, no matter how "wet" the GRP is, it can only hold a maximum of around 2% to 3% water, and the GRP itself only forms maybe 20% at most of a typical sailing yacht's total displacement. So 2% of 20% of a 12,000 lb displacement 35-footer is 48 to 64 lbs of water that could be dried out by an osmosis treatment. This would alter the waterline by a tiny fraction of an inch. The stories you hear of boats floating several inches higher on their waterline after osmosis treatments are not due to removing weight - it just means that the new waterline boot-top is often painted several inches higher after the treatment, to disguse the imperfect joint line between original gelcoat topsides and epoxy treated bottom.

The only time a boat can really put on major amounts of weight through water absorption is with foam-cored or balsa sandwich hulls, where the core material itself has become saturated, though this is more usually due to damage rather than normal use over time. |

|

Quite a few surveyors websites will tell you about osmosis

- look at http://www.yachtsurvey.com/BuyingBlisterBoat.htm for a fairly laid-back American essay on the subject by a surveyor,

much of which is to the effect that blisters are not usually that

much of a problem, apart from being unsightly. This being America,

of course, other articles on his website refer to new boat warranties

that specifically recommend not keeping boats in the water for

more than two weeks.

More information can also be found on Nigel

Clegg's website - see this PDF document for another explanation of osmosis and it treatment

Unfortunately the very experienced surveyor Jeffrey Casciani-Wood's

website, which used to have a very comprehensive article on osmosis,

has closed down, as he has retired from business. Extracts from

the articles there are however still online at http://www.mckaymarine.com.au/Surveying%20GRP.htm |

This page is written by John Wilson

of Yachtsnet Ltd., from the point of view of a very experienced

small boat sailor, former owner of a yacht "with osmosis"

(the boat was purchased knowing it had blisters), and yacht broker. |

|

© Yachtsnet Ltd. 2000/2026 |

|